Vermicomposting

Vermicomposting is the mechanism through which worms are used to turn organic materials (usually waste) into a humus-like material called vermin-compost. The goal is to handle the material as fast and efficiently as possible.

In a number of important ways, vermicompost seems to be generally superior to conventionally generated compost:

- In compost production, vermicompost is superior to most composts as an inoculant.

- Worms have a variety of other potential uses on farms, including importance as an animal feed of high quality.

- Vermicomposting and vermiculture are potential sources of additional income for organic farmers.

The following advantages have Vermicompost over chemical fertilizers

- This restores the microbial community containing fixers of nitrogen, solubilizers of phosphate, etc.

- Provides plants with large and minor nutrients

- Improves soil texture and soil water retention ability

- Provides good soil aeration, thereby promoting root growth and the production of beneficial soil microorganisms

- Reduces the use of pesticides to control pathogens in plants

- Improves soil structural stability and thus prevents soil erosion

- Improves grain/fruit quality due to higher sugar content.

At the same time, the start of the vermicomposting process is more complex than the traditional composting process.

- It can be quicker, but it usually requires more effort to do so

- It requires more space because worms are feeders on the surface and will not operate more than one meter deep in material.

- It is more susceptible to stress from the environment such as temperature, freezing conditions, and drought

- Perhaps most importantly, more start-up assets are needed, either in cash or in time and labor.

Vermicomposting of waste in field containers

- For successful vermin-composting beds, it is advisable to go for 20 ft long, 3 ft wide, and 2 ft deep field pits of optimum length.

- In one place a number of such beds are to be prepared.

Vermicomposting on the floor

- Vermicomposting can be used in ground heaps instead of open pits.

- Dome-shaped beds are made (with organic waste) and vermicomposting is used.

- The optimum heap size can be 10 ft in length / 3 ft in width / 2 ft in height.

Materials required for vermicomposting

- Agricultural waste (weed, soybean, chickpea, mustard, etc.) was used for vermicomposting

- New manure

- Dung ratio (1:1 on the basis of dry weight)

- Earthworm: 1000–1200 adult worms (approximately 1 kg per quintal of waste)

- Water: 3–5 L per week per pit or heap

Preparation of mixed compost under the shade of trees by pit and heap methods

Under the tree shade, which was around 2 ft above ground to prevent the intrusion of rainwater into the pits, open permanent pits of 10 ft long, 3 ft wide and 2 ft deep were created. Brick walls were built above the pit floor and five to six holes perforated in the pit wall for aeration in a diameter of 10 cm. Nylon screen (100 mesh) blocked the holes in the wall to prevent earthworms from escaping from the pits. Partially decomposed dung (dung about 2 months old) was spread to approximately 3–4 cm thick at the bottom of the pits. This was accompanied by adding1:1 (w / w) layer of litter/residue and dung. Then another layer of litter/crop residue was added in the same ratio up to a height of 2 ft. During the time of decomposition, the moisture content is retained at 60–70 percent. Jute bags (gunny bags) were spread evenly on the material surface to facilitate the maintenance of appropriate moisture and temperature conditions. Watering was often achieved by the sprinkler. The materials are allowed to decompose to maintain the temperature for 15–20 days because the process will pass the thermophilic stage in about 3 weeks to reach the mesophilic level. Earthworms are inoculated with 10 adult earthworms (1.160.3 g each) per kg of waste material in the pit or heap, adding a total of 500 worms to each pit or heap. For 110 days the products are allowed to decompose. Far sooner (75–85 days) the forest litter was decomposed than the crop residue (110–115 days). In the heaping process, the waste materials and partially decomposed dung (1:1 w / w) are rendered in heaps of 10 ft in length approximately 3 ft in width approximately 2 ft in height, and during inoculation, channels are made by hand and earthworm at 1 kg per quintal of waste and are inoculated and then watered by sprinkler. Jute pieces of fabric are used as a substitute for wrapping.

Abstract

Abstract

Solid and hazardous waste disposal in urban areas around the world is a major challenge. The waste generated from various human activities, both industrial and domestic, can result in health hazards and have a negative impact on the environment without an effective and efficient waste management system. The attempt has been made in this section to identify the impacts of solid and hazardous waste on society. The commonly used methods of treatment and disposal are discussed along with design criteria for designing either a solid or a hazardous waste management system. Depending on the type of waste, the reader can suggest a design depending on the type of waste, its characteristics, and disposal methods after reading this.

Sanitary and ecological aspects of the disposal of wastewater sludge

Composting and vermicomposting

Composting in the presence of oxygen as a form of biological biowaste decomposition contributes significantly to the recovery and preservation of several macro-and micronutrients from sewage sludge in the soil. Its alternative, vermicomposting, is a modern, inexpensive and environmentally friendly biotechnology in which earthworms are used to decompose organic matter as natural bioreactors (Suleiman et al., 2017). Their metabolic activity and collaboration with microorganisms contribute to a 40-60% reduction in size, an increase in nutrient bioavailability for plants, a decrease in the C / N ratio, and a decrease in the availability of certain hazardous pollutants such as metals (Rorat et al., 2015). Although composting can be considered highly beneficial and a low-cost sewage-to-matter technique that allows organic nutrients to be returned into the ecosystem, it still causes some significant environmental issues. Significant losses of nitrogen and greenhouse gas (GHG) emissions can be reported due to the rapid degradation of organic nitrogen (Sánchez-Monedero et al., 2010). The introduction of various bulking agents, such as agricultural waste and alkaline modifications such as lime, zeolite, and bentonite, can partially reduce these effects. Biochar has also recently been considered an effective agent for reducing greenhouse gases, ammonia, and extractable emissions of ammonia (Malińska et al., 2014; Awasthi et al., 2016). While these effects can be partially eliminated, researchers are concerned about the input of potentially toxic metal elements and thus their possible accumulation in the soil horizon for several (Fang et al., 2017). The same type of risk is associated with the presence of other chemical compounds and pharmaceuticals as well as certain pathogens that can survive the process.

Abstract

Abstract

In the world of environmental engineering, sewage sludge treatment is currently a huge challenge. New active wastewater treatment technologies have resulted in an improvement in the quality of the final effluent, but have significantly increased the amount of sewage sludge generated, which increases annually. There are two opposing points of view on the reuse of these “wastes.” Dehydrated sewage sludge is mainly regarded as a source of nutrients and organic matter that can be used as a fertilizer for agriculture or as an environmental alteration in the remediation of polluted sites or in the development of “anthroposoils.”On the other hand, recycled sewage sludge is seen as a potential source of contamination of the soil by organic and inorganic pollutants and pathogens; potentially toxic elements (such as zinc, copper, cadmium, lead, silver, etc.); polycyclic aromatic hydrocarbons (PAH); polychlorobiphenyls (PCB); biocides and phytopharmaceuticals; pharmaceuticals, products for personal care (PPCP) and residues;

Secondary Production: Heterotrophic Organism Activities — Soil Fauna

Earthworm Management

There is also a growing interest in the potential for earthworms to improve soil during land reclamation or in degraded agricultural sites. In many situations, the introduction of earthworms may be desirable. Techniques have been developed to inoculate large-scale areas without earthworms (e.g. reclaimed polders) and to introduce organisms that can perform desired functions. It is usually necessary at the time of inoculation to have favorable soil conditions and/or to provide refuge from which earthworms can disperse. It often fails to introduce earthworms into unfavorable environments.

Mixed-species earthworm groups can affect a wider range of soil processes, such as the turnover of organic matter as well as soil structural properties than a single species can (Lee, 1995). Such assemblies may include one or more anecdotal species that make deep vertical burrows and cast residues on the surface and bury and one or more endogenic species that feed on dead roots and organic matter below ground and make horizontal burrows. The inclusion of epigeic species can accelerate the decomposition on the soil surface of plant residues.

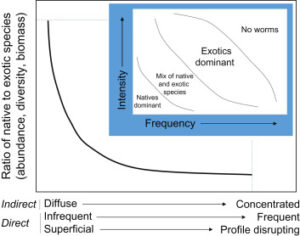

The relationship between invasion, native species, and the establishment of non-native species in soils where there are still native species (i.e. unglaciated soils) is not so simple, but this interaction may include competitive exclusion or other biotic interactions. In such soils, pure assemblages of native earthworm species are extremely rare, especially if tillage or other soil profile disturbance has occurred. However, for non-native species to be established, these profile-disrupting disturbances need not affect vast areas of land. Researchers found that roads built through habitats otherwise undisturbed can serve as corridors for the introduction of non-native earthworms in less disturbed habitats. Workers have established a correlation between land-use history and the prevalence of non-native earthworms in soil invertebrate populations in other unglaciated soils in North America, with a clear indication that vegetation and soil disturbances contribute to European species dominance of the earthworm population.

Multifunctions of sludge in a Phytobiome — Application forest and plantation including microbial aspects

Heavy metal and microcontaminant problems

The principle of using sewage sludge as a fertilizer has a few major drawbacks to consider. Wrongly processed sewage sludge can have a wide variety of unwanted features and, as a result, adverse effects on a particular environment. Because of this threat, awareness about reducing the risks of using organic waste such as sewage sludge as a soil modification is important. Previously, farming processes used to increase soil productivity have often resulted in adverse effects on soil fertility and quality due to the lack of sludge contaminant regulations (Karathanasis et al., 2005). For the first time in the European Union, the reuse of sewage sludge in agriculture has been governed by Council Directive 86/278/EEC, which mostly tackles the risks to human health from sewage-borne metal pollution. Meanwhile, countries like Portugal have published revised legislation implementing the requirements for pathogenic microorganisms and organic pollutants in sewage sludge added to the soil (Petersen et al., 2003b). Countries such as Portugal restrict the drawbacks of the application of sewage sludge in their Decree-Law No. 276/2009, which restricts HM material values and pathogenic microorganisms occurrence.

The possible reuse of sewage sludge for soil fertilization faces a number of technical problems, including the constant threat of discovering harmful contaminants and even the simple fact that year-round sludge is generated and fertilizer application occurs only once or, at best, twice a year. The solution to this problem can be to create storage and composting facilities with other natural fractions, including agricultural or food waste. Such composting will help to overcome issues such as the high concentration of heat, lack of stability, or infection with human or animal pathogens. Composting is also highly recommended because of the high temperatures produced during this process, which kills all parasites and pathogenic microorganisms. It must be taken into account that poor quality or improperly treated sludge often poses a threat to the environment that can lead to accumulation and leaching of toxic elements. Transferring metals from sewage sludge to soil and then groundwater and plants can pose a potential threat to health and the environment as it is understood that heavy metals are extremely persistent in soil and can stay there for thousands of years. Because of their adsorption on clays, hydrous oxides, and organic matter, metals applied with such sewage sludge can be stored in the soil. In contrast, soil pH is also an important factor in the preservation of metals. As a result, CaCO3 is found to increase metal retention and, overall, the heavy metal persistence is high in soils with more basic pH. A large number of previous studies dealt with this issue, and some of them show that metal migration is negligible and some have shown a significant amount of sewage sludge leached Zn, Cr, and Cu.

Earthworm Vermistabilization and detoxification of sugar sludges

Vermicomposting is a process based on earthworms and microorganisms whose joint activity allows for organic waste degradation and detoxification as well as transformation into a material to be used for agronomic purposes. This environmentally friendly approach is cost-effective and is the strongest among other methods of remediation. Enzymatic practices lead to toxic metal immobilization in the earthworm gut, which indicates that Vermitechnology is an efficient process for heavy metal remediation from industrial organic waste/sludges. It can be inferred that for agricultural applications with reduced toxicity, Vermiremediation theoretically transforms sugar industrial sludges into nutrient-rich organic manure.

Waste from the domestic and food industries is turned into biofertilizer

Wastewater

Therefore, the combination of anaerobic dry toilet and vermicomposting appears to be an ideal approach to waste management, including waste from urban households. The drug, terra preta, will tackle the soil depletion and food insecurity issues that are prevalent in many parts of the world. With the added value of enhanced urban agriculture, which can be combined with local greywater recycling, TPS could become critical in designing highly efficient, environmentally friendly houses and housing areas. Therefore, with the development of local added value, TPS will close regional cycles and boost hygienic conditions and soil fertility in a sustainable way. Questions like the problem of macronutrients and also micronutrients still need to be addressed.

Treatment of Solid Waste

Municipal solid waste (MSW) is highly organic in nature, making vermicomposting a suitable alternative to safe, hygienic and cost-effective disposal. Earthworms feed on organics and convert the material into plant nutrient-rich castings (ejected matter). Cast chemical analysis reveals 2 times the magnesium available, 15 times the nitrogen available, and 7 times the potassium available relative to the surrounding soil. Physical and biochemical is the action of earthworms in the waste vermicomposting process. The physical process involves surface aeration, mixing as well as actual grinding, while the biochemical process is affected by microbial substratum decomposition in the earthworm intestine (Hand et al., 1988). Several studies have shown that organic waste vermicomposting accelerates the stabilization of organic matter (Neuhauser et al., 1998) and provides chelating and phytohormonal elements with a high content of microbial matter and stabilized humic substances. There are several references to the potential of earthworms in solid waste vermicomposting, particularly household waste (Edwards, 1980). Advanced vermicomposting systems are based on an elevated reactor’s top feeding and bottom discharge, providing stability and control over key temperature, humidity and aeration areas. Price and Phillips (1990) created an improved mechanical separator with a hybrid action novel to extract live earthworms from vermicomposts. Vermicomposting also offers other benefits; certain earthworms can also be used for unique wastes such as those from medical facilities and those with high protein or pig feed levels, as well as for nematode control.

Toxic Waste From Municipality

- Methods of Energy Recovery From Wastes: The other way to use the waste is to extract the energy they produce. Thermal conversions (incineration, fast and slow pyrolysis, gasification, generation of refuse based fuel (RDF)), biochemical (composting, vermicomposting, anaerobic digestion / bio methanation) and chemical transformations (trans-esterification and other processes for converting plant and vegetable oils into biodiesel) are the most widely used methods of energy recovery. Depending on the type, property, and quantity of biomass feedstock, the desired source of fuel, end-use specifications, environmental standards, economic conditions, and project-specific factors, the option of the conversion process.

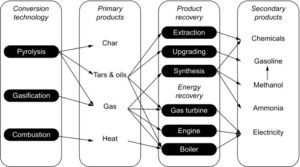

2. Thermal Conversions: The thermal conversion methods available for thermal treatment of solid waste are combustion, gasification, and pyrolysis. As illustrated in Fig. From the operation of these methods, various by-products are produced and different energy and material recovery technologies can be used to handle these products.

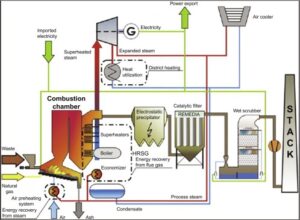

3. Incineration: Incineration is a general waste management method as it eliminates waste in mass by about 70% and volume by 90%. This also saves energy by turning water into steam to operate a steam power plant using the heat content. This system includes a lined furnace, fire grate, and air blowers and ranges from 50 kg to 20 tons per hour in strength. The incineration process takes place between 750 ° C and 1000 ° C and is combined with the method of producing steam and electricity. For the following reasons, mass incineration without pretreatment with electricity generation of municipal solid waste is considered to be the most efficient and economical option.

(i) Most of the wastes will burn without giving rise to noxious products of combustion (HCI, HF, SO2, and NOx) in significant quantities.

(ii) The volume and mass occupied by the waste are greatly reduced. A small volume of incombustible residues is left. The heat of combustion is recovered in a waste heat boiler for steam generation.

(iii) Waste in its initial form may be objectionable in nature, containing decaying organic matter and whatever.

For civil engineering building, the by-product from the incineration is used as supporting materials. Their granularity design and compact features make them a replacement for road construction aggregates. The residue also finds its use as a source for alkali-activated materials, as an adsorbent agent for extracting toxic elements from sewage and landfill gases, as a soil replacement in agricultural operations, as a partial or complete substitute for the manufacture of ceramic-based products, as a landfill cover and as a biogas output enhancer. The residue can contain hazardous materials such as lead, zinc and other heavy metals. The fly ash can be reused to extract fine particles from such hazardous materials by hydrocyclonizing them. The incinerator residue is mixed with concrete and used in the building of lightweight. The use of the built element has shown increased strength.

Pyrolysis

Of the disposal methods, waste pyrolysis is of interest, a thermal treatment process that involves waste heating in an oxygen-free atmosphere. Numerous advantages reported by the pyrolysis process are:

(a) a significant reduction in waste volume (< 50 percent–90 percent)

(b) the production of solid, liquid and gaseous waste fuels

(c) the production of storable/transportable fuel or chemical feedstock

(d) a limited environmental issue

(e) a beneficial process as energy is derived from renewable sources such as municipal solid waste or wastewater.

Conventional pyrolysis (slow pyrolysis) occurs in significant portions at a slow rate of heating with solid, liquid and gaseous materials. It is an ancient method used mainly for the processing of charcoal. As they are formed, vapors can be continually extracted. But at low temperature (850–1250 K) and/or fuel, at high temperature (1050–1300 K), strong pyrolysis is correlated with tar. Currently, with very short residence time, the preferred technology is quick or flash pyrolysis at high temperatures. Quick pyrolysis (more specifically known as thermolysis) is a process in which, in the absence of oxygen, a product such as biomass is heated rapidly to high temperatures.

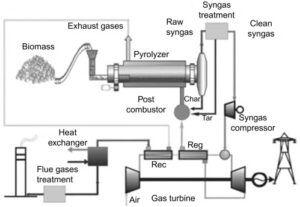

Gasification

Gasification is a process in which partial biomass combustion is conducted in order to produce gas and char at the first stage and subsequently to reduce the product gases, primarily CO2 and H2O, by the charcoal in CO and H2. The system also produces some methane and other higher hydrocarbons (HCs) depending on the reactor’s model and operating conditions. Gasification may generally be characterized as the thermochemical transformation of a solid or liquid carbon-based material (feedstock) into a fuel gaseous substance (combustible gas) by the supply of a gasifying agent (another gaseous compound). The gasification agent allows the feedstock to be quickly converted into gas by means of different heterogeneous reactions. The fuel gas includes CO2, CO, H2, CH4, H2O, trace quantities of higher hydrocarbons, inert gases in the gasifying agent, and various pollutants such as small char particles, dust, and tars. If the process is not carried out using an oxidizing agent, it is called indirect gasification and involves an external source of energy.

Steam is the indirect gasification agent most widely used because it is easily produced and increases the hydrogen content of the fuel gas. The generation of unsustainable amounts of waste per capita is a common issue among all developed countries. The quantity of waste material produced has also increased to an unsustainable level as societies have grown. In addition to increasing public awareness of the damage caused to the environment, there is an urgent need to prepare and adopt sustainable and efficient waste management and treatment strategies that have become a priority for many local authorities. A gasification system is made up of three fundamental elements:

(1) a gasifier for the processing of fuel gas

(2) a gas clean-up system for the extraction of hazardous compounds from fuel gas

(3) an energy recovery device. The system is completed with appropriate subsystems that are helpful in managing environmental impacts (air pollution, solid waste and wastewater production). For a proper and efficient gasification process, a sufficiently homogeneous carbon-based material is needed. Consequently, in the gasification process, some forms of waste can not be treated and extensive pre-treatment (refuse-derived fuel) is required for certain types. Alternatively, there are several forms of waste that are specifically suitable for the process; Waste from paper mills, mixed plastic waste, waste from forestry and farm waste. The gasifier is a reactor in which a feedstock is converted into fuel gas. There are three specific gasifier types:

(1) stationary bed

(2) fluidized bed

(3) indirect gasifier.

The gasification system is a potential alternative to the waste incinerator for the thermal treatment of homogeneous carbon-based waste and heterogeneous waste pretreated.

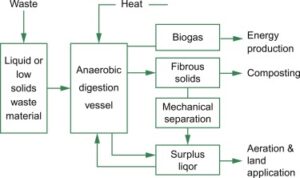

Biochemical Conversion

Biochemical processes of processing use bacteria enzymes and other microorganisms to break down biomass. Microorganisms are used in many situations to conduct the process of conversion: anaerobic digestion, fermentation, and composting. Biochemical conversion is one of the few that offers environmentally friendly guidance for MSW to acquire energy oil. Anaerobic digestion is helpful in reducing and extracting energy from agricultural solid waste. Essentially, a possible feedstock for anaerobic digestion is the organic fraction of MSW[16–18]. The organic fraction can usually be digested and the biogas can be used either for combined heat and power (CHP) or as a transportation fuel; however, a non-recyclable non-organic fraction of MSW can either be incinerated or gasified. The temperature rises and can reach as high as 65 ° C during the decomposition process of this organic fraction, but begins to fall after 1–2 months. Nevertheless, the fermentation process is going on for a long time, producing a variety of gasses, including small amounts of CO and H2S. Methane is produced under anaerobic conditions. Methane (high heat, gas) can be converted to methanol effectively.

Abstract

Abstract Abstract

Abstract